Expansion tanks are vital components in plumbing and heating systems, ensuring the smooth operation and longevity of equipment like boilers, water heaters, and closed-loop heating systems. These devices help manage pressure fluctuations within the system, safeguarding it from damage caused by excessive pressure buildup. In this article, we’ll dive into what an expansion tank does, why it is important, and how it works, with a focus on its use in residential and commercial settings.

What is an Expansion Tank?

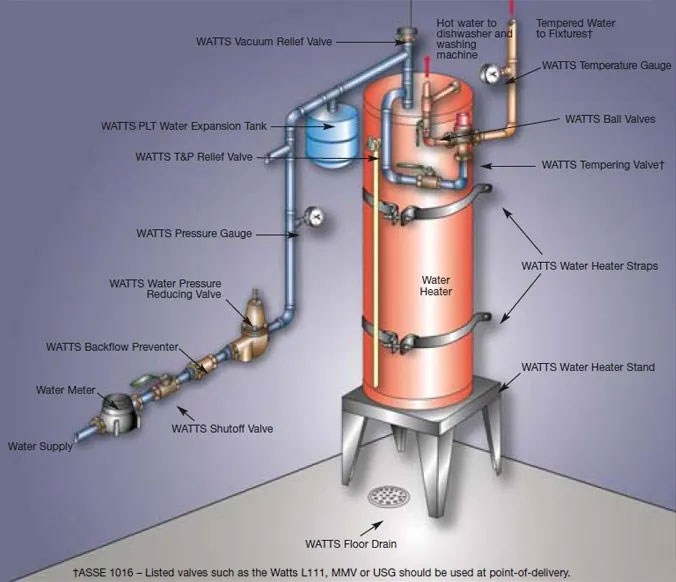

An expansion tank is a small tank, often found in plumbing or heating systems, designed to accommodate the expansion of water as it heats up. When water is heated, it expands—a property known as thermal expansion. In closed-loop systems (such as central heating systems or water heaters), the expansion of water can cause an increase in pressure, potentially leading to pipe damage, leaks, or system failure. The expansion tank prevents this by acting as a buffer, allowing water to flow into the tank, thus relieving the pressure in the system.

These tanks are typically cylindrical in shape, with two main chambers separated by a flexible diaphragm. One side of the tank is filled with air, while the other is connected to the plumbing system where the expanding water enters.

How Does an Expansion Tank Work?

When water is heated in a closed system, it expands and requires more space. Since the water has nowhere to go in a sealed system, the pressure will increase unless there is a relief mechanism. This is where the expansion tank comes into play.

Here’s how it works:

- Water Heats Up: As the water in the system is heated, it expands.

- Pressure Increases: In a closed system without an expansion tank, the additional volume of water would cause pressure to build up within the system. This can lead to stress on pipes, joints, and other system components.

- Expansion Tank Absorbs the Pressure: As the pressure rises, the excess water enters the expansion tank. Inside the tank, a diaphragm or bladder allows the water to flow in while compressing the air on the other side.

- Pressure Balancing: The air cushion in the expansion tank compresses to absorb the increased pressure, preventing damage to the system and keeping the pressure at safe levels.

- Water Returns: Once the water cools down and contracts, it is pushed back into the system, and the expansion tank returns to its original state.

The system is thus balanced, and the risk of pressure-related damage is minimized.

Why is an Expansion Tank Important?

Expansion tanks are crucial for the health of plumbing and heating systems. Here are several reasons why:

1. Prevents Pressure Build-Up

The primary function of an expansion tank is to relieve excessive pressure in closed-loop systems. Without one, pressure can build up to dangerous levels, causing pipes to burst or valves to leak. This can result in costly repairs and even potential safety hazards.

2. Increases System Lifespan

By managing the pressure, expansion tanks help extend the lifespan of the entire plumbing or heating system. Components like boilers, water heaters, and pipes are subject to less wear and tear when pressure is properly regulated.

3. Reduces Water Hammer

Water hammer is a phenomenon where sudden pressure changes in the system cause loud banging noises in the pipes. This occurs when water suddenly changes direction or flow, which can happen when a valve is closed too quickly. An expansion tank helps mitigate water hammer by providing a place for water to expand and contract, reducing sudden pressure changes.

4. Protects Water Heater and Boiler Systems

Water heaters and boilers are significant investments in any household or commercial building. A faulty system due to pressure imbalances can result in reduced efficiency, higher energy costs, and eventual system failure. An expansion tank ensures the system runs smoothly, protecting these essential appliances.

5. Prevents Leaks

In systems without an expansion tank, the pressure build-up can cause leaks around seals, joints, or valves. Over time, this can cause significant water damage. An expansion tank alleviates this pressure, reducing the risk of leaks.

Types of Expansion Tanks

There are two main types of expansion tanks used in plumbing and heating systems:

1. Diaphragm Expansion Tanks

In a diaphragm expansion tank, the interior is divided into two chambers: one for water and one for air. These chambers are separated by a flexible diaphragm. As water heats up and expands, it enters the water chamber, compressing the air on the other side. The compressed air creates a counterpressure that prevents the system from experiencing a dangerous pressure increase. This is the most common type of expansion tank used in residential and commercial systems.

2. Bladder Expansion Tanks

Bladder expansion tanks work similarly to diaphragm tanks, but they use a rubber bladder instead of a diaphragm to separate the water and air chambers. When water expands, it fills the bladder, which then compresses the air in the tank. These tanks tend to be more durable and are commonly found in larger, more demanding heating systems.

How to Choose the Right Expansion Tank

Selecting the correct expansion tank depends on several factors, including the size of your heating system, the type of water heater or boiler in use, and the volume of water in the system. To ensure optimal performance, it is essential to choose a tank that is properly sized.

1. System Size

The size of your heating or plumbing system plays a key role in selecting an expansion tank. Larger systems require larger tanks to handle the increased volume of expanding water. Installing an undersized tank can result in insufficient pressure relief, rendering the tank ineffective.

2. Water Heater Type

Certain water heaters, such as high-efficiency models, may have specific requirements when it comes to expansion tanks. Some manufacturers recommend specific tank types or sizes to ensure compatibility.

3. Pressure Rating

Make sure the expansion tank’s pressure rating matches the pressure of your system. Most domestic systems operate at a pressure of 12-15 psi (pounds per square inch), but commercial systems may require higher pressure ratings.

4. Installation Location

Expansion tanks are typically installed near the water heater or boiler. Consider the available space when selecting a tank, as larger tanks will require more room. Additionally, ensure that the tank is accessible for maintenance and inspection.

How to Maintain an Expansion Tank

Expansion tanks are generally low-maintenance, but periodic checks can help ensure they continue functioning properly. Here are a few steps to maintain an expansion tank:

1. Check Pressure Regularly

It’s important to check the air pressure in the tank to ensure it matches the system’s pressure. If the air pressure is too low, the tank will not be able to effectively absorb the expanding water, leading to potential pressure build-up.

2. Inspect for Leaks

Check the tank and its connections for any signs of leaks. Even a small leak can reduce the effectiveness of the expansion tank and cause damage to the surrounding area.

3. Replace the Diaphragm or Bladder

Over time, the diaphragm or bladder inside the expansion tank may wear out or rupture. If this happens, the tank will no longer be able to separate air from water, and the tank will need to be replaced.

Common Problems with Expansion Tanks

Despite their reliability, expansion tanks can experience problems over time. Here are a few common issues to watch out for:

1. Over-Pressurization

If the system pressure exceeds the tank’s capacity, the tank may not be able to absorb the excess water, leading to over-pressurization. This can happen if the tank is undersized or if the air pressure in the tank is not properly maintained.

2. Waterlogging

A waterlogged expansion tank occurs when the diaphragm or bladder ruptures, allowing water to fill the entire tank. This reduces the tank’s ability to absorb pressure and can cause the system to become over-pressurized. If you suspect a waterlogged tank, it should be replaced as soon as possible.

3. Air Leakage

If the air side of the tank develops a leak, the tank will lose its ability to compress the air, reducing its effectiveness. Regularly checking the pressure can help identify and prevent this problem.